Blogs

Read our Blogs

Our Blogs

Electrical Maintenance: A Key to Business Continuity

Electrical Maintenance: A Key to Business Continuity

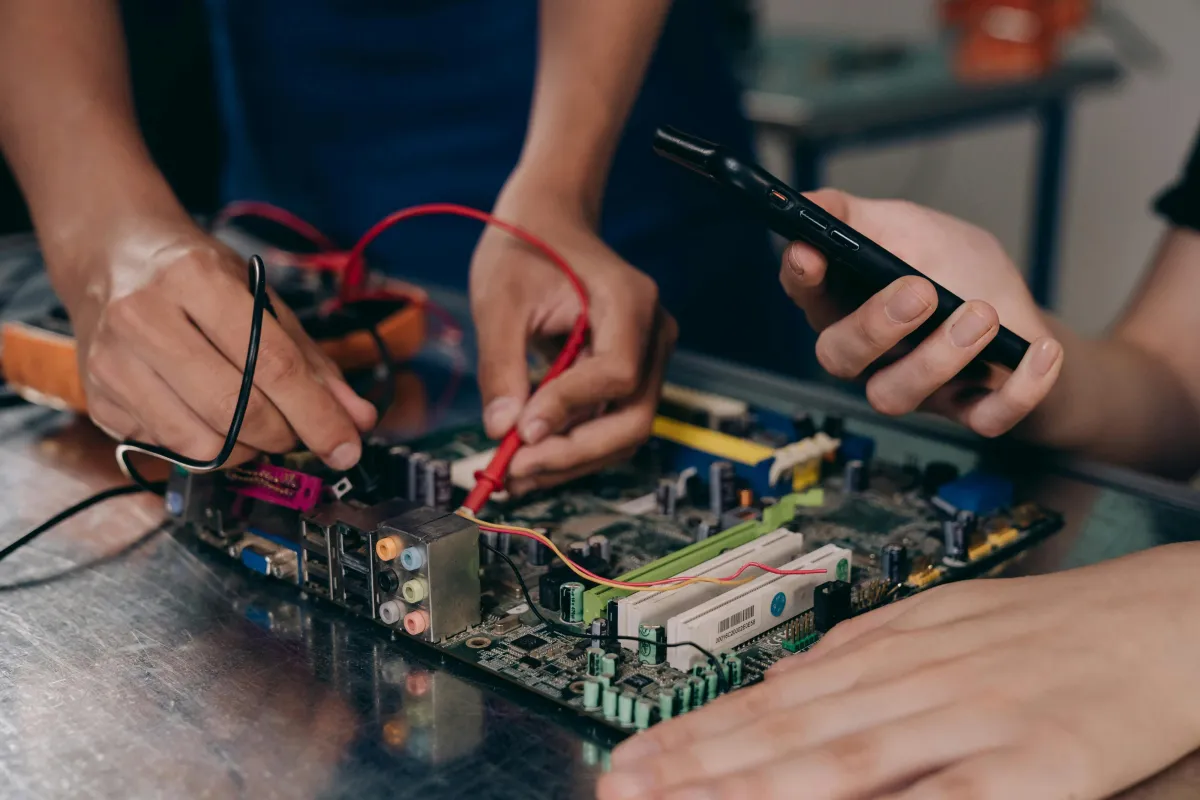

Did you know that unscheduled downtime caused by electrical failures can cost commercial businesses up to 25% in lost productivity? Our dependability on machines is unquestionable, but so is the risk when they fail. This article delves into the significance of regular electrical maintenance, offering you a detailed checklist of strategies to prevent the unexpected interruptions that could halt your business operations. By implementing a robust electrical maintenance plan and adhering to safety regulations, you unlock the potential for extended equipment lifespans and, most importantly, uninterrupted business continuity. Discover how to minimize risks and maintain operational efficiency, ensuring your commercial endeavors thrive without the shadow of preventable electrical issues.

Understand the Importance of Regular Electrical Maintenance

Regular electrical maintenance is fundamental to business operations, ensuring systems run smoothly. Neglecting elements like electrical wiring, light fixtures, and circuit breakers can lead to significant hazards. Scheduled maintenance checks are instrumental in preventing downtime, pinpointing small issues before they escalate into major disruptions. This section delves into the risks associated with overlooking electrical systems and underscores the advantages of routine evaluations. By proactively maintaining infrastructure, businesses safeguard both efficiency and safety.

Recognize the Risks of Neglecting Electrical Systems

When businesses overlook electrical systems, the repercussions can be significant, affecting both lighting and equipment functionality. Flickering lights or a faulty light switch may seem minor but can signal deeper electrical issues that, if ignored, can lead to costly emergency repairs or replacement. Regular checks, such as portable appliance testing, can catch these early warning signs, assuring continuous operation and safeguarding against unexpected outages that disrupt business continuity.

Moreover, neglecting routine maintenance poses a substantial risk to safety. Faulty wiring or malfunctioning equipment can result in hazardous working conditions, potentially leading to fires or electrical shocks. By investing in consistent electrical system evaluations, companies not only ensure the prolonged lifespan of their infrastructure but also protect their employees, minimizing the risk of accidents and reinforcing a commitment to a secure workplace environment.

Identify the Benefits of Scheduled Maintenance Checks

Scheduled maintenance checks directly contribute to the longevity of a business's electrical systems. With an electrician carrying out routine inspections and compliance verifications, such as adherence to the standards of BS 7671, companies can ensure their operations are not undercut by electrical failures. These preventive measures help maintain consistent electricity flow, reducing the likelihood of downtime and the expenses tied to emergency fixes.

Businesses that prioritize electrical maintenance also tend to enjoy a stronger reputation, as reliability and safety become part of their brand promise. By addressing potential electrical issues proactively, companies demonstrate their commitment to upholding high standards, providing peace of mind to customers and employees alike. In turn, this fosters trust and can even contribute to a competitive edge in the market where dependability is highly valued.

Develop a Comprehensive Electrical Maintenance Plan

Developing a comprehensive electrical maintenance plan is essential for safeguarding occupational safety and health, preventing injury, and minimizing downtime. The plan must begin with a thorough assessment of your current electrical infrastructure. Critical knowledge obtained through this inspection informs the establishment of clear electrical maintenance goals and objectives. This approach ensures that a systematic and effective maintenance schedule is in place, reducing risks and promoting uninterrupted business operations.

Thoroughly Assess Your Current Electrical Infrastructure

To lay the foundation for a steadfast electrical maintenance plan, an exhaustive assessment of your electrical infrastructure is imperative. This detailed evaluation, conducted by seasoned engineering professionals, identifies any existing or potential issues that could impede efficiency and safety. Their expertise provides an accurate snapshot of the system's health, informing maintenance strategies that ensure seamless business continuity.

A comprehensive review extends beyond a cursory glance, delving into the infrastructure's design, installation quality, and wear-and-tear status. Such an approach not only bolsters the operational dependability but also aligns with best practices in safety and maintenance, equipping businesses with the insights needed to preempt disruptions and maintain an exemplary standard of workplace safety.

Set Clear Electrical Maintenance Goals and Objectives

Establishing the importance of electrical maintenance starts with setting specific goals that ensure the continuous operation of high voltage systems, wires, switches, and related infrastructure. These objectives should not only aim to maintain a safe environment but also to extend the lifespan of electrical components. By defining a set of measurable and achievable aims, organizations create a roadmap that caters to both functionality and safety requirements.

Within the context of a comprehensive electrical maintenance strategy, the company can then identify critical checkpoints for diagnosing potential hazards and inefficiencies. By prioritizing the maintenance of electrical systems, businesses mitigate risks and uphold a high standard of operational integrity. This proactive approach contributes to avoiding unexpected breakdowns, ensuring a well-maintained and safe environment for all stakeholders.

Implement Effective Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is a cornerstone for avoiding electrical failures and ensuring business continuity. Regular inspections of electrical equipment are crucial for detecting signs of wear, overheating, and fuse degradation that could lead to failure, heat buildup, and accidents. Simultaneously, properly training staff on electrical safety procedures is integral to maintaining health and safety standards. These proactive steps are vital in preventing operational interruptions and fostering a safe work environment.

Schedule Regular Electrical Equipment Inspections

Scheduling regular inspections of commercial electrical systems is a proactive measure that can avert wear and tear from escalating into costly repairs. These inspections help to ensure that all components, including wirings and moisture-prone areas, remain free from water damage, thus protecting both property and personnel. By conducting these routine assessments, businesses can verify that their electrical infrastructure complies with regulatory standards, ultimately preserving the operational integrity and safety of the workplace.

A comprehensive electrical maintenance plan incorporates regular reviews focused on detecting early signs of damage or deterioration, allowing for prompt remediation. Addressing issues related to commercial electrical equipment promptly ensures not only the functionality of the system but also supports regulatory compliance, preventing legal repercussions that can arise from negligence. Recognizing the impact of weather, usage, and time on electrical systems allows for targeted interventions that maintain a property’s electrical reliability and prevent disruption to business activities.

Properly Train Staff on Electrical Safety Procedures

Staff training in electrical safety is not just a regulation compliance issue; it's a cornerstone of effective maintenance strategies. Educating employees on how to safely handle electrical devices and respond to fire alarm system activations is critical. This expertise helps prevent accidents, ensures energy conservation, and extends the lifespan of electrical equipment, thus supporting uninterrupted business operation.

Offering hands-on workshops led by electrical engineering professionals can transform technical knowledge into practical skill sets. When employees grasp the principles of electricity and the proper use of tools and equipment, they are better equipped to detect anomalies that may require maintenance or immediate attention, reducing the risk of equipment failure and promoting a culture of safety and efficiency.

Ensure Compliance With Electrical Safety Regulations

Ensuring compliance with electrical safety regulations is pivotal for any business aiming to uphold continuity and prevent power outages. Engineers play a key role in regularly updating companies on industry standards, from the proper use of extension cords to comprehensive fire safety measures. Conducting thorough safety audits and inspections is essential in this process, serving as a guard against equipment failure and workplace accidents. Through these practices, management can confidently maintain a safe, functional environment.

Regularly Stay Updated With Electrical Industry Standards

Staying abreast of British standards in electrical safety is a requisite for businesses, including landlords managing rental properties, to ensure that power supply systems are compliant and secure. Regular updates on electrical regulations, delivered via email or other communications, enable landlords and businesses to mitigate risks, which can influence insurance premiums and overall safety. Adherence to the latest standards is not a mere formality but a strategic move to ensure the durability and reliability of electrical infrastructures, underpinning uninterrupted business operations.

For businesses, conforming to British standards signals to clients, employees, and stakeholders a commitment to safety and operational excellence. When landlords align their properties with these safety regulations, they protect not only the physical integrity of their buildings but also their reputability in the market. By maintaining an email address dedicated to receiving updates from regulatory bodies, a company can easily keep its practices current and reduce the chances of unexpected power supply issues that could disrupt ongoing activities, emphasizing a proactive stance on electrical maintenance.

Conduct Thorough Safety Audits and Inspections

Conducting thorough safety audits and inspections is a non-negotiable aspect of facility management, serving as a crucial investment in a business's continued operation and safety. These meticulous examinations, led by experts conversant with Health and Safety Executive standards, target wear in electrical components, ensuring the integrity of transformers and other critical equipment. By identifying wear early, businesses can take corrective measures, thus avoiding costly downtime and ensuring the health and safety of all personnel.

Engaging in comprehensive electrical audits transforms a facility's risk management approach, cementing the health and safety of employees as a top priority. Specialists in facility management scrutinize each element of a business's electrical system, from the resilience of safety guards to the reliability of emergency cut-offs. This proactive investment in regular inspections safeguards against disruptions, maintaining both the physical and financial well-being of the enterprise.

Minimize Downtime Through Proactive Electrical Maintenance

Proactive electrical maintenance is vital for minimizing downtime and ensuring continuous business operations. By continuously monitoring equipment performance metrics, businesses can address issues before they lead to failures. Troubleshooting electric heating systems, charging stations, and electric generators, as part of the wider infrastructure maintenance, helps prevent unexpected outages and maintains system efficiency. The following sections will delve into effective monitoring strategies and troubleshooting methods to keep electrical infrastructure running reliably.

Continuously Monitor Equipment Performance Metrics

Monitoring equipment performance metrics stands as a crucial aspect of proactive electrical maintenance within any modern factory. By leveraging technology to track variables such as voltage, current, and resistance, businesses can predict and prevent costly downtime resulting from short circuits and other malfunctions. This ongoing surveillance allows asset managers to make informed decisions about maintenance, upgrades, or replacements, ensuring optimal operation and cost-effective pricing strategies.

Continuous oversight of electrical systems through performance metrics serves not only to protect the integrity of factory operations but also to fine-tune energy consumption and maintenance schedules. Advanced monitoring tools can detect even subtle changes that may indicate pending issues, such as slight overheating or energy inefficiencies, allowing for immediate action. This proactive approach minimizes disruption and lays the groundwork for enduring business continuity and asset longevity.

Address Issues Before They Lead to Failures

In the context of retail businesses, where customer service is paramount, having a tool to preemptively monitor and address electric issues, such as solar panel degradation or frequency irregularities, is invaluable. This foresight helps maintain continuous operations and reinforces a retailer's commitment to seamless customer experiences. Proactive resolution of these issues prevents downtime that can affect sales and customer trust, thus protecting the business's reputation and revenue.

Utilizing frequent, scheduled maintenance checks as a preventive tool ensures that electrical systems support the high demands of customer service environments. This strategy is especially critical for operations reliant on solar panels, where energy consistency directly influences performance. By identifying and solving issues before they evolve into failures, businesses can avoid the significant costs and negative customer impacts of unplanned electrical outages.

Extend the Lifespan of Vital Electrical Equipment

Extending the lifespan of vital electrical equipment is essential for businesses to manage expenses and ensure continuity. Investing in high-quality replacement electrical parts not only ensures adherence to certification standards but also supports critical functions like water heating. In addition, strategically planning for electrical equipment upgrades is crucial to keep operations in Wales running smoothly. The upcoming sections will provide detailed information on how to select the best components and plan upgrades effectively.

Invest in High-Quality Replacement Electrical Parts

Choosing high-quality replacement parts for electrical equipment is a strategic decision that serves the dual purpose of optimizing energy efficiency and reducing long-term financial strain on the budget. Premium components are designed to handle consistent voltage demands and enhance the overall functionality of electronics, thereby assuring customers of reliable service. Smart investment in these superior parts can lead to significant savings by minimizing the frequency and cost of future repairs or replacements.

In the realm of electrical maintenance, businesses that prioritize the use of high-grade electrical parts demonstrate foresight and a commitment to sustainability. These components often exceed standard requirements, offering improved resistance to wear and a longer lifespan, which is pivotal to maintaining uninterrupted operations. By investing in parts that align with the latest technological advances, companies can reduce energy consumption and provide a seamless customer experience, affirming their reputation as a reliable provider.

Strategically Plan for Electrical Equipment Upgrades

Strategic planning for electrical equipment upgrades is crucial for warehouses looking to enhance safety and reduce the risk of fire. A thorough risk assessment can identify critical systems that require modernization, ensuring that the warehouse's operations in South Wales remain compliant with safety regulations and resilient against electrical faults. By preempting equipment obsolescence, businesses can proactively mitigate hazards and maintain a robust supply chain.

Undertaking a methodical approach to upgrading electrical equipment, informed by a detailed risk assessment, ensures that organizations in South Wales can maintain continuity in the face of evolving demands. This strategic foresight not only extends the lifespan of electrical assets but also equips facilities to handle future growth, safeguarding against operational disruptions from outdated systems and positioning the business advantageously for long-term success.

Conclusion

Electrical maintenance emerges as an essential practice to ensure the smooth operation of businesses, preventing costly downtime and ensuring employee safety. Regularly assessing electrical systems, setting maintenance goals, and staying current with industry standards form the backbone of robust electrical infrastructure management. Proactive strategies, such as scheduling timely inspections and investing in quality parts, are critical to extending the life of vital equipment and maintaining business continuity. Ultimately, consistent electrical maintenance is not just a technical necessity but a strategic business decision that underpins the reliability and longevity of any operation.